TECHNOLOGY

MJF 3D Printing

Multi Jet Fusion Powder Bed

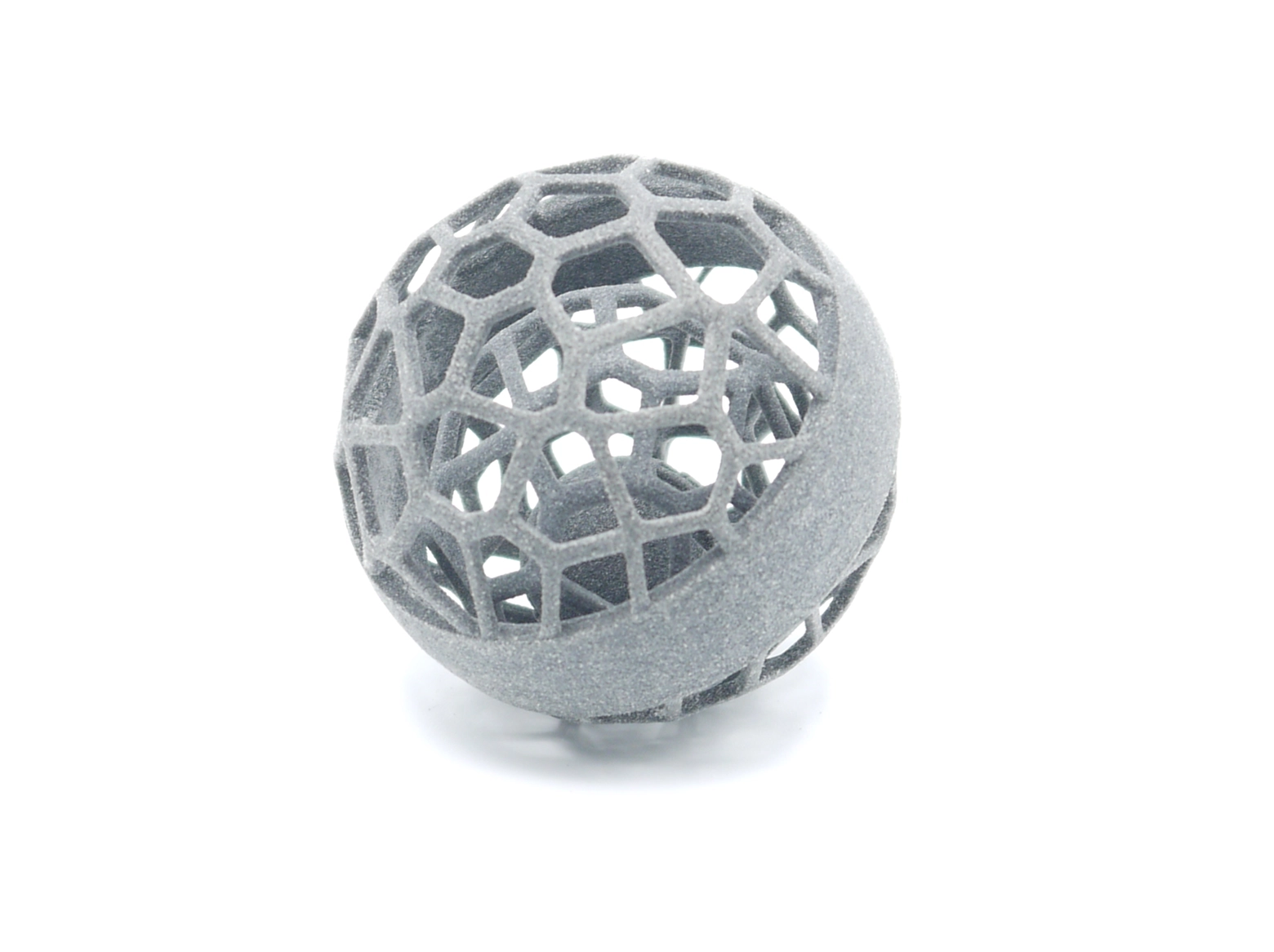

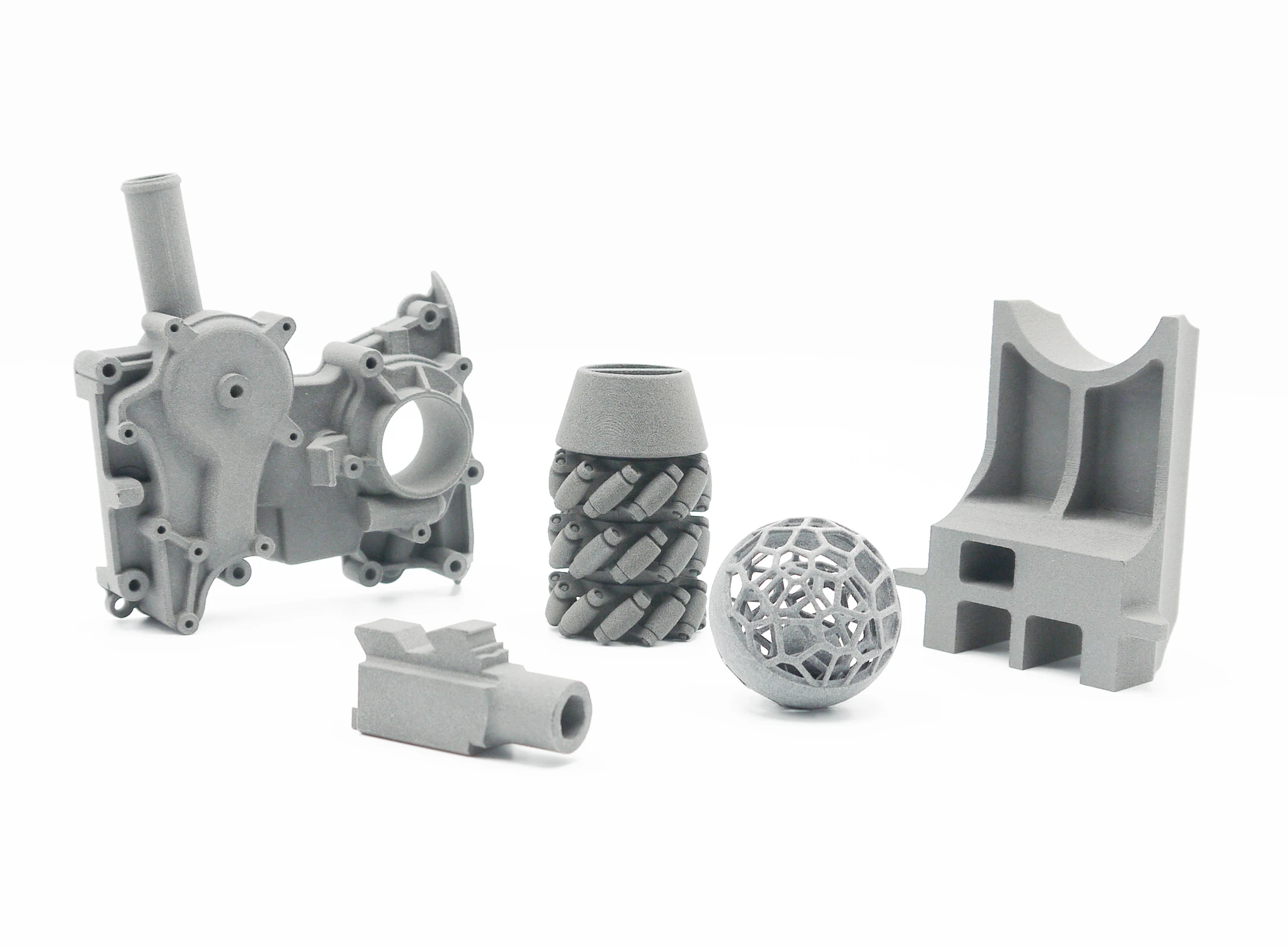

It offers speed and the ability to produce complex geometries without support structures. The resulting parts have a uniform surface finish and nearly isotropic mechanical properties, comparable to injection molding but with the flexibility of additive manufacturing.

What is MJF 3D Printing?

Multi Jet Fusion (MJF) is a 3D printing technology developed by HP that deposits fusing and detailing agents onto thin layers of polymer powder, which are then fused layer by layer using thermal energy. This process creates solid parts with high density, excellent dimensional accuracy, and outstanding mechanical properties. It is perfect not only for functional prototyping but also for short production runs.

Minimum Design Tolerances

PARAMETER

VALUE

1.0 mm

0.5 mm

1.0 mm

0.5 mm

0.4 mm

0.08 mm (80 μm)

MATERIALS

Wide Selection of Materials for MJF 3D Printing

Nylon PA 12 (MJF)

Nylon PA 12 is the most common material used in MJF, offering an excellent combination of mechanical strength, dimensional stability, and long-term durability. It is ideal for functional prototypes, housings, gears, tooling, and general end-use parts.

Properties:

-

- Good mechanical and thermal strength

- Low moisture absorption and excellent chemical stability

- Uniform surface finish, easy to dye or coat

- Design freedom for complex geometries and integrated moving parts

Looking for a fast way to manufacture parts?

With our MJF technology, you can get high-quality functional parts quickly, efficiently, and cost-effectively for your project.

MANUFACTURING SERVICES

Discover Our Technologies

At Manfacter, we offer professional-quality 3D printing solutions to bring your ideas to life. From rapid prototyping to end-use parts production, we guarantee high-quality, fast, and cost-effective results. We use industry-leading technologies such as SLS, FDM, SLA, and MJF, allowing us to adapt to the needs of any sector.

It offers speed and the ability to produce complex geometries without support structures.

It offers the highest resolution level and accuracy among all additive manufacturing technologies.

Ideal for engineering thanks to its ability to produce complex geometries.

It offers a wide variety of materials and the capability to produce large parts.

It offers speed and the ability to produce complex geometries without support structures.

It offers the highest resolution level and accuracy among all additive manufacturing technologies.

Ideal for engineering thanks to its ability to produce complex geometries.

It offers a wide variety of materials and the capability to produce large parts.

Frequently Asked Questions About MJF 3D Printing

What types of parts can be manufactured with MJF?

Functional parts, housings, technical components, tooling, short production runs, and prototypes with consistent finishes and good mechanical strength.

What tolerances does MJF technology offer?

±0.3 mm up to 100 mm. Beyond that, ±0.3% for larger dimensions. If fine adjustments are required, post-machining can be requested.

Is MJF a good option for mechanical parts?

Yes. The parts have isotropic mechanical strength, good stiffness, and dimensional stability. It is ideal for lightweight structural components.

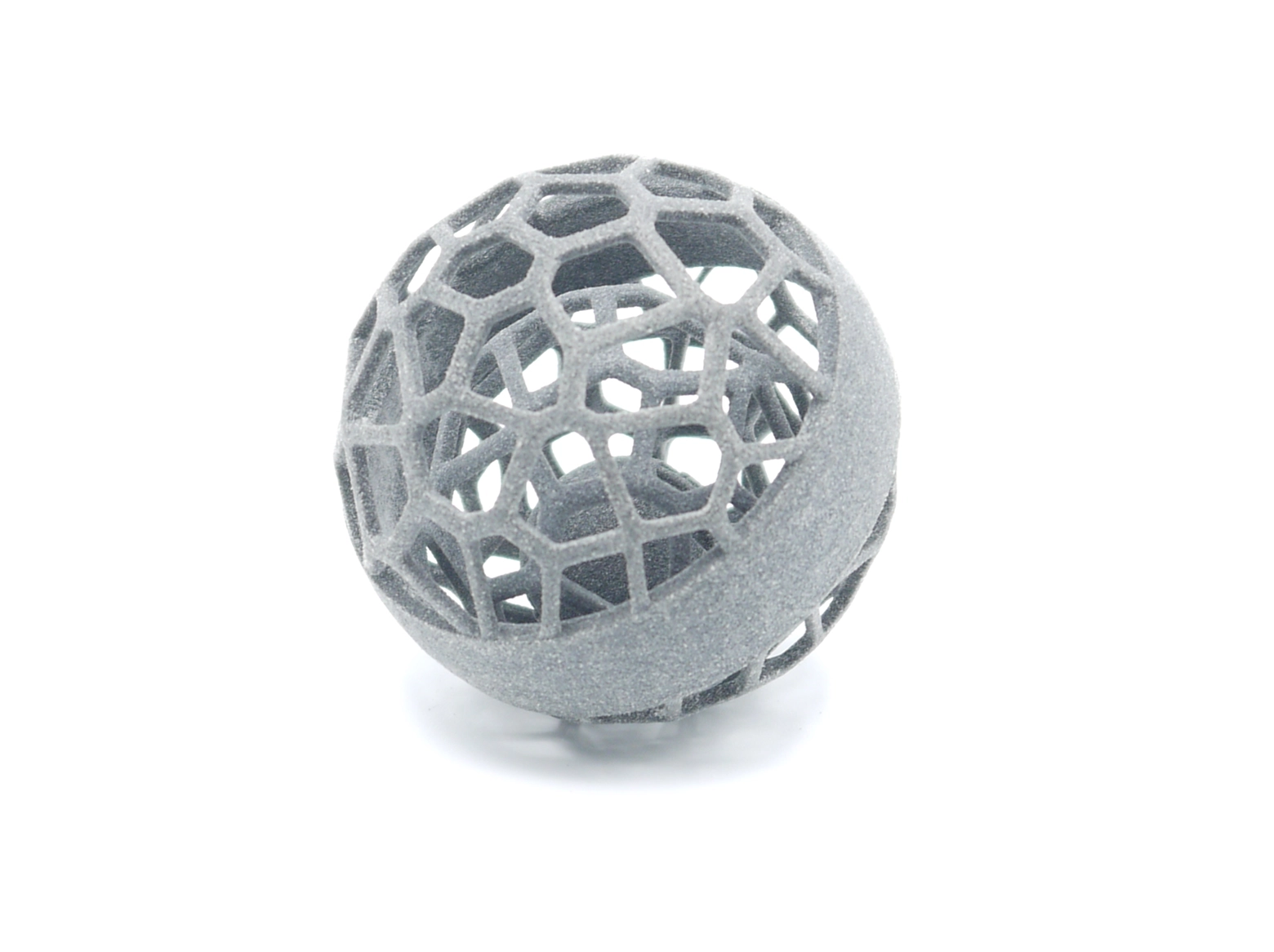

What is the surface finish of the parts like?

Matte gray with a slightly rough texture. It can be improved through sandblasting, dyeing, or painting if additional aesthetics or functionality are required.

How long does it take to produce a part with MJF?

Between 2 and 5 business days, depending on the volume, complexity, and workload of the printing center. At Manfacter, we show you the exact lead time in real time.

What file formats can I upload to get a quote in MJF?

You can upload your 3D files in STL, OBJ, and 3MF formats.

Can series be manufactured with MJF?

Yes. It is one of the most competitive 3D technologies for short- and medium-run series (from 10 to 1,000 units) thanks to its speed and low unit cost.

What post-processing options are available?

We offer standard finish or black dyeing.