TECHNOLOGY

SLA 3D Printing

Stereolithography

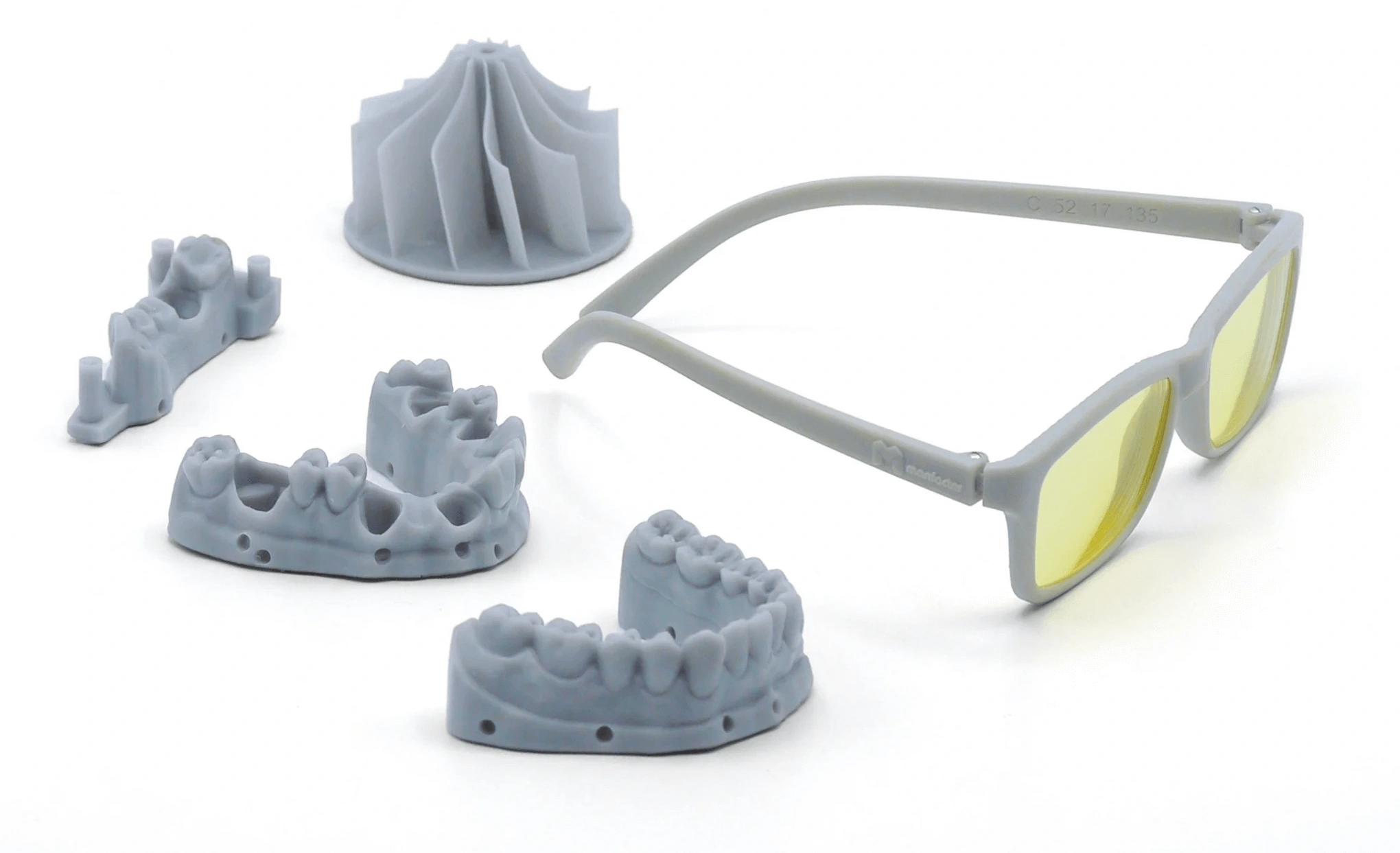

It offers the highest level of resolution and precision among all 3D printing technologies. Applicable across any sector, primarily dental, medical, and engineering, thanks to its wide range of biocompatible materials and exceptional surface finishes.

What is SLA 3D Printing?

SLA (Stereolithography) 3D printing is an additive manufacturing technology that uses an ultraviolet laser to solidify liquid resin layer by layer, creating parts with high precision and smooth finishes. This technique enables the production of highly detailed parts and is widely used in fields such as dentistry, jewelry, and industrial prototyping, thanks to its high resolution and versatility in materials.

Minimum Design Tolerances

PARAMETER

VALUE

0.6 mm

0.4 mm

0.5 mm

0.5 mm

0.2 mm

0.03 mm, 0.05 mm, 0.1 mm

MATERIALS

Wide Selection of Materials for SLA 3D Printing

Standard Resin

Ideal for creating visual prototypes and parts with precise details and smooth surfaces. This material is perfect for displays and scale models.

Properties:

-

- Strong and rigid

- High precision and dimensional stability

- Smooth surface finish

- Available in multiple colors

ABS-Like Resin

It mimics the properties of ABS plastic, offering an excellent combination of rigidity and durability—ideal for functional prototypes.

Properties:

-

- High mechanical strength

- Good surface finish

- Suitable for functional parts and detailed prototypes

Nylon-Like Resin

Versatile, high-performance material ideal for parts that require mechanical strength and durability. Commonly used in the automotive and aerospace industries.

Properties:

-

- High wear and impact resistance

- Low friction and high durability

- Detailed surface finish

MANUFACTURING SERVICES

Discover Our Technologies

At Manfacter, we offer professional-quality 3D printing solutions to bring your ideas to life. From rapid prototyping to end-use parts production, we guarantee high-quality, fast, and cost-effective results. We use industry-leading technologies such as SLS, FDM, SLA, and MJF, allowing us to adapt to the needs of any sector.

It offers speed and the ability to produce complex geometries without support structures.

It offers the highest resolution level and accuracy among all additive manufacturing technologies.

Ideal for engineering thanks to its ability to produce complex geometries.

It offers a wide variety of materials and the capability to produce large parts.

It offers speed and the ability to produce complex geometries without support structures.

It offers the highest resolution level and accuracy among all additive manufacturing technologies.

Ideal for engineering thanks to its ability to produce complex geometries.

It offers a wide variety of materials and the capability to produce large parts.

Looking for a fast way to manufacture parts?

With our SLA technology, you can get high-quality functional parts quickly, efficiently, and cost-effectively for your project.

Frequently Asked Questions About SLA 3D Printing

How does SLA differ from other 3D printing technologies?

SLA offers superior precision and detail, along with smooth surfaces without the need for extensive post-processing. Unlike FDM, which uses filament, or SLS, which uses powder, SLA employs liquid resin that enables the creation of fine and highly detailed geometries.

Is it safe to use SLA parts in functional applications?

Yes, although it depends on the type of resin used. Some SLA resins offer mechanical and thermal resistance, making them suitable for low-stress functional applications. However, their strength is generally lower compared to technologies such as DMLS for metals.

What types of parts are ideal for SLA 3D printing?

SLA technology is ideal for producing detailed prototypes, conceptual models, presentation parts, and applications where surface finish and precision are top priorities. It is also widely used in dentistry, jewelry, and in creating molds for investment casting.

What are the design recommendations for SLA 3D printing?

For best results, it is recommended to avoid walls that are too thin (minimum 0.4 mm), ensure the design allows for support removal, and add reinforcements in areas with delicate structures. In addition, parts should be oriented to minimize the need for supports and to optimize the surface quality.

What type of file should I provide for printing?

STL and STEP files are the most common formats for SLA, as they preserve the geometry and details of the part. You can upload them directly to our platform and get a quote for your parts in seconds.

What finishes are available for SLA-printed parts?

SLA parts typically have a smooth and detailed surface finish. Additional treatments such as sanding, painting, coating, or polishing can be applied to enhance appearance and strength, depending on the application.

What level of accuracy and resolution can be achieved with SLA?

SLA accuracy is typically around ±0.05 mm, and layer thickness can be as fine as 25 microns. This enables high-detail resolution, making it ideal for parts with complex and precise features.

Does SLA printing require post-processing?

Yes, SLA-printed parts must be washed to remove excess resin and then cured under UV light to achieve maximum strength and stability. Additionally, they can be sanded and polished to improve the finish.

Is it possible to manufacture a functional prototype with SLA before mass production?

Yes, SLA 3D printing is ideal for detailed prototypes that allow design verification before moving into mass production. This method is widely used to validate a product both visually and functionally in its early stage.

Can unused resin be reused in SLA?

Yes, resin that was not used during a print can be reused as long as it is not contaminated. However, it is important to filter and inspect the resin regularly to ensure the quality of future prints.

What care do SLA parts require in long-term applications?

SLA parts are sensitive to prolonged exposure to UV light, which can weaken them and make them brittle over time. For extended durability, it is recommended to store them in dark environments or apply protective coatings if they will be used outdoors.