Do you design well… or manufacture poorly?

A design for manufacturing that ignores the specifics of 3D printing is bound to suffer from costly mistakes. A part may look flawless on screen but fail in production if it doesn’t account for 3D printing tolerances. In this guide, we break down seven common mistakes and show you how design for manufacturing can pragmatically avoid them.

Why does design for manufacturing remain a bottleneck?

In many projects, modeling is done without considering real 3D printing. Once the STL reaches production, unexpected costs and delays appear. The root cause is almost always a lack of attention to 3D printing tolerances and the relationship between geometry and material. Building a strong design-for-manufacturing workflow prevents most errors before the machines start, streamlining the entire value chain

Identifying 3D printing errors before production is the fastest way to cut costs and lead times.

The 7 design mistakes you must avoid (and how to fix them)

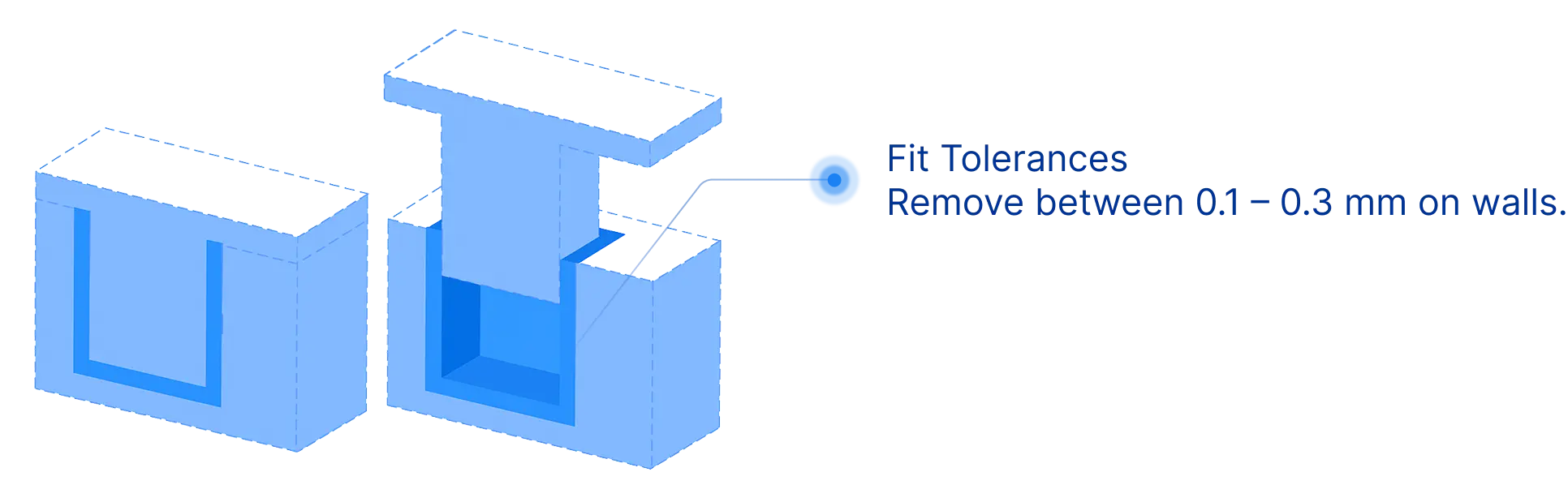

Ignoring Process Tolerances

Each technology has specific tolerances that must be respected at the design stage.

Example: In FDM printing, subtract 0.1 mm to 0.3 mm on walls that need to fit mechanically with other parts.

- What happens: Designers model flush fits without clearance, leaving parts loose or jammed.

- Solution: Ask your provider for their official 3D printing tolerance chart and apply it to your CAD.

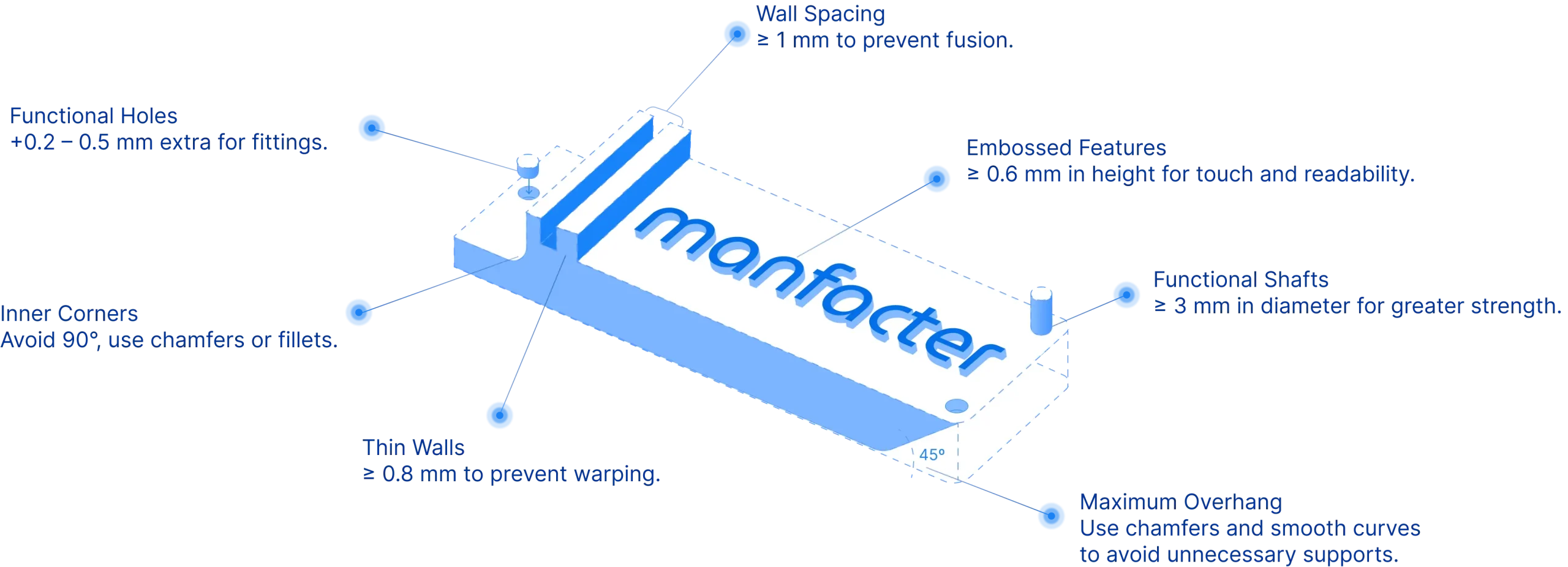

Designing Hard-to-Produce Geometries

Deep cavities, thin walls, or sharp angles increase cost and complicate manufacturing.

This is a very common mistake in 3D printing. An unrealistic design may require special tools, additional supports, or multiple operations.

Example: In 3D printing, walls thinner than 1 mm may warp.

- What happens: Thin walls (<0.8 mm) or sharp angles create stress and weaken the part.

- Solution: Increase wall thickness, round off corners, and split the part if necessary. This prevents many design errors before wasting material.

Download the 3D Printing Design Guide

Skipping Manufacturer Validation

A small adjustment in time can save days of rework.

Many design errors are only detected after a part is produced. This can be avoided with prior validation by the supplier.

- What happens: Prototypes are sent to production without review, leading to expensive failures.

- Solution: Send the STL and request a DFM analysis. On Manfacter, you can get it instantly on the platform. Validate your model here.

Aligning design for manufacturing with the machine reduces iterations and realistically adjusts 3D printing tolerances.

Choosing the Material at the End

Material impacts manufacturing method, tolerances, thermal behavior, and cost. Not all materials have the same strength or are suitable for the same technology.

Designing without defining the material can lead to problems.

- What happens: Designing for PLA and later switching to PA12 can create contraction, stiffness, or structural issues.

- Solution: Define the polymer at the concept stage so tolerances and performance are locked in from the start.

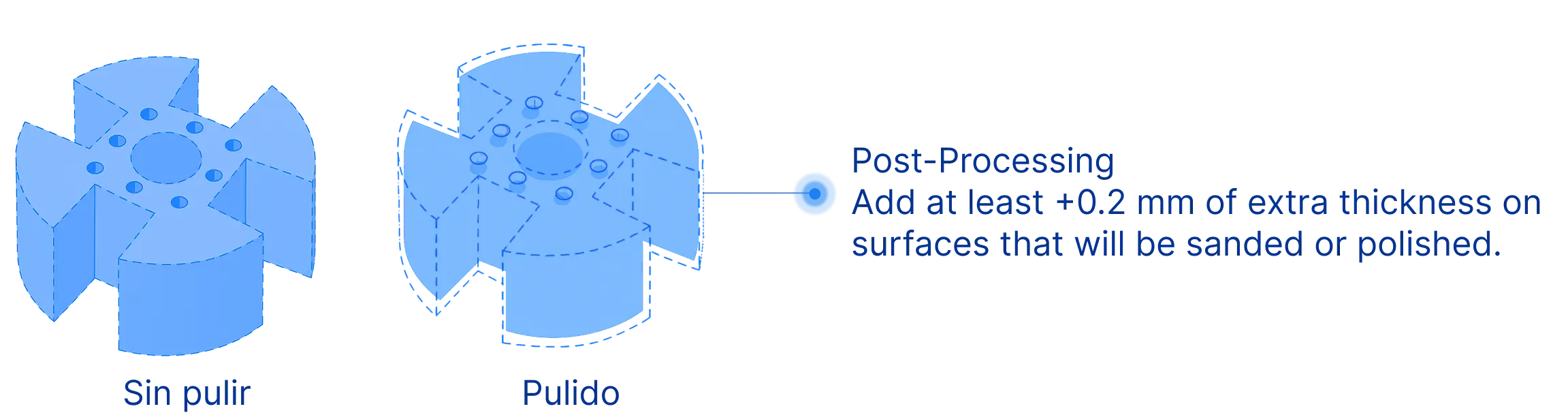

Ignoring Post-Processing

Many parts require sanding, UV curing, or cleaning.

- What happens: Sanding or painting adds microns, ruining fits.

- Solution: Leave extra allowance and reference faces. Integrating post-processing is a key part of DFM.

Forgetting the Final Function

Sometimes the design is optimized for the machine but not for real use.

- What happens: The part prints perfectly but fails in service.

- Solution: Design with assembly, environment, and maintenance in mind.

Not Documenting Iterations

- What happens: Changes are lost, and old errors reappear.

- Solution: Version CAD files and record tolerance updates. Your team will always know which variant works.

Good Design = Better Manufacturing

By incorporating 3D printing tolerances from the beginning and avoiding these seven mistakes, your design for manufacturing will reduce costs, shorten lead times, and deliver optimal parts right the first time.