Digital manufacturing for industrial parts

Upload your 3D model, get instant pricing and lead time.

Receive your parts in just a few days.

Secure

Your 3D files are uploaded confidentially.

Fast

Instant pricing

Parts delivered in days.

Flexible

From prototypes to mass production.

ALONGSIDE LEADING COMPANIES

MANUFACTURING SERVICES

From prototypes to mass production

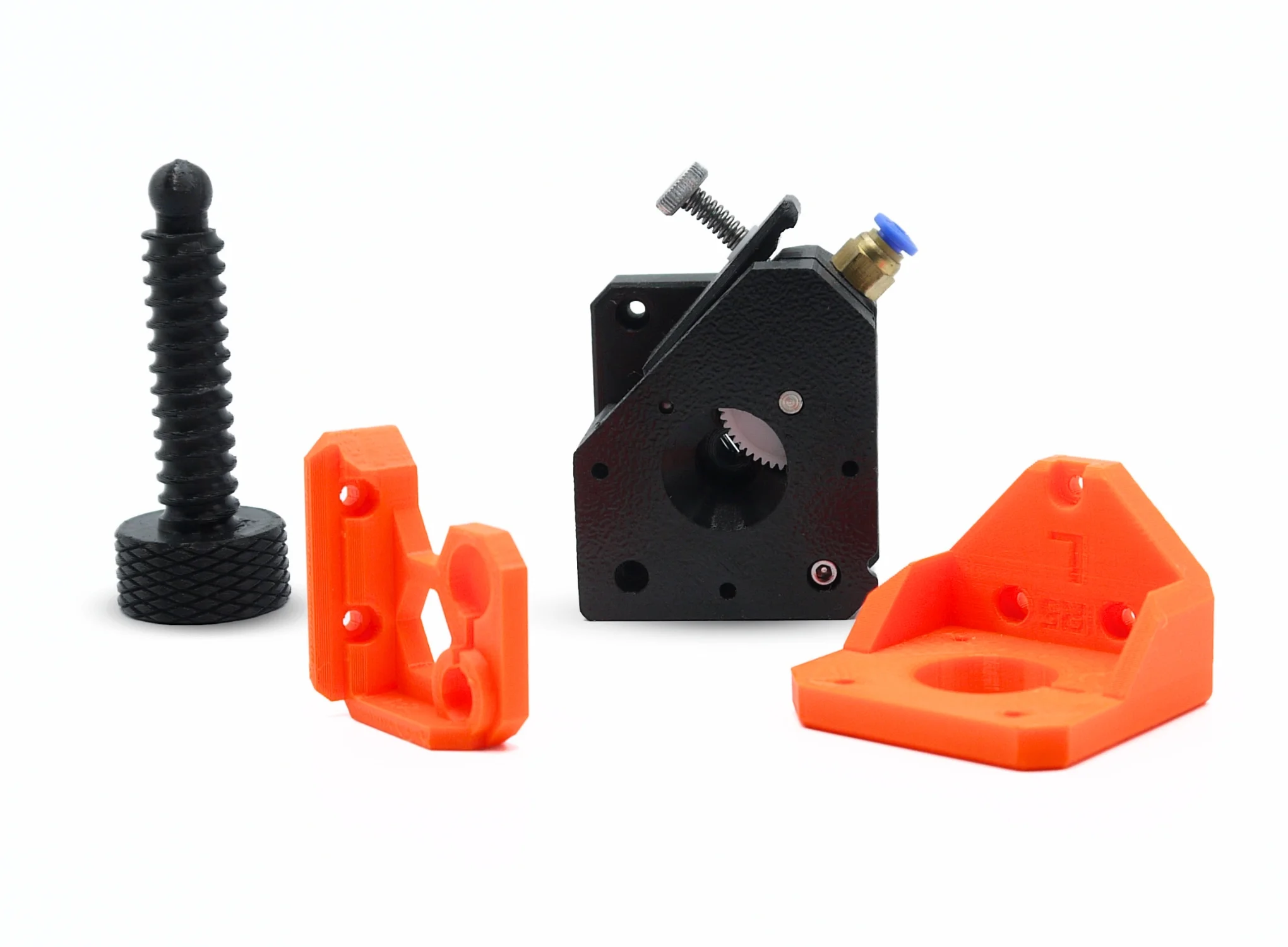

What is 3D printing?

3D printing is a process that creates three dimensional objects from a digital design, building the part layer by layer. It is ideal for functional prototypes, complex geometries and on demand production, without the need for molds or tooling.

Benefits of 3D printing

- Wide range of technologies available such as FDM, SLA, SLS, MJF and DMLS.

- Ideal for validating designs or producing short runs without molds.

- Professional finishes ready for functional use.

What is CNC machining?

CNC machining, or Computer Numerical Control machining, is an automated manufacturing process that uses computer programs to control machine tools such as mills and lathes, removing material from a solid block to create high precision components.

Benefits of CNC machining

- Direct production from drawing or 3D model.

- Custom finishes such as anodizing, sandblasting, painting and more.

- Milling and turning in a wide range of materials.

What is injection molding?

Injection molding is a manufacturing process used to produce plastic parts in high volumes. The material is melted and then injected at high pressure into a mold, where it cools and solidifies to take the desired shape.

Benefits of injection molding

- Molds custom designed from your drawings.

- Compatible with the main technical thermoplastics.

- Consistent parts in large volumes.

What is sheet metal bending?

Sheet metal bending is a plastic deformation process used to fold a metal sheet to create a three dimensional shape, applying controlled force without removing material. A press brake with a punch and die is used to bend the sheet to the desired angle.

Benefits of sheet metal bending

- Custom bending radii according to thickness.

- Ideal for structures, housings and metal brackets.

- Increases the structural strength of the sheet.

What is laser cutting?

Laser cutting is a digital manufacturing process that uses a concentrated and high power beam of light to cut, engrave or mark materials with great precision. A computer controls the machine to guide the beam along the desired path, vaporizing or melting the material to perform the cut or engraving.

Benefits of laser cutting

- Enables very precise cuts with fine details.

- Full repeatability for short and medium series.

- Ideal for flat parts, structures and prototypes.

What is waterjet cutting?

Waterjet cutting is an industrial process that uses a high pressure jet of water, often mixed with an abrasive, to cut a wide variety of materials with precision and without generating heat. This technique is very versatile and can cut materials such as metals, stone, glass, ceramics and rubber without damaging them with heat.

Benefits of waterjet cutting

- Effective solution for thick materials or parts that are sensitive to heat.

- Clean cut without altering mechanical properties.

- Allows thicknesses up to 100 mm with a uniform finish.

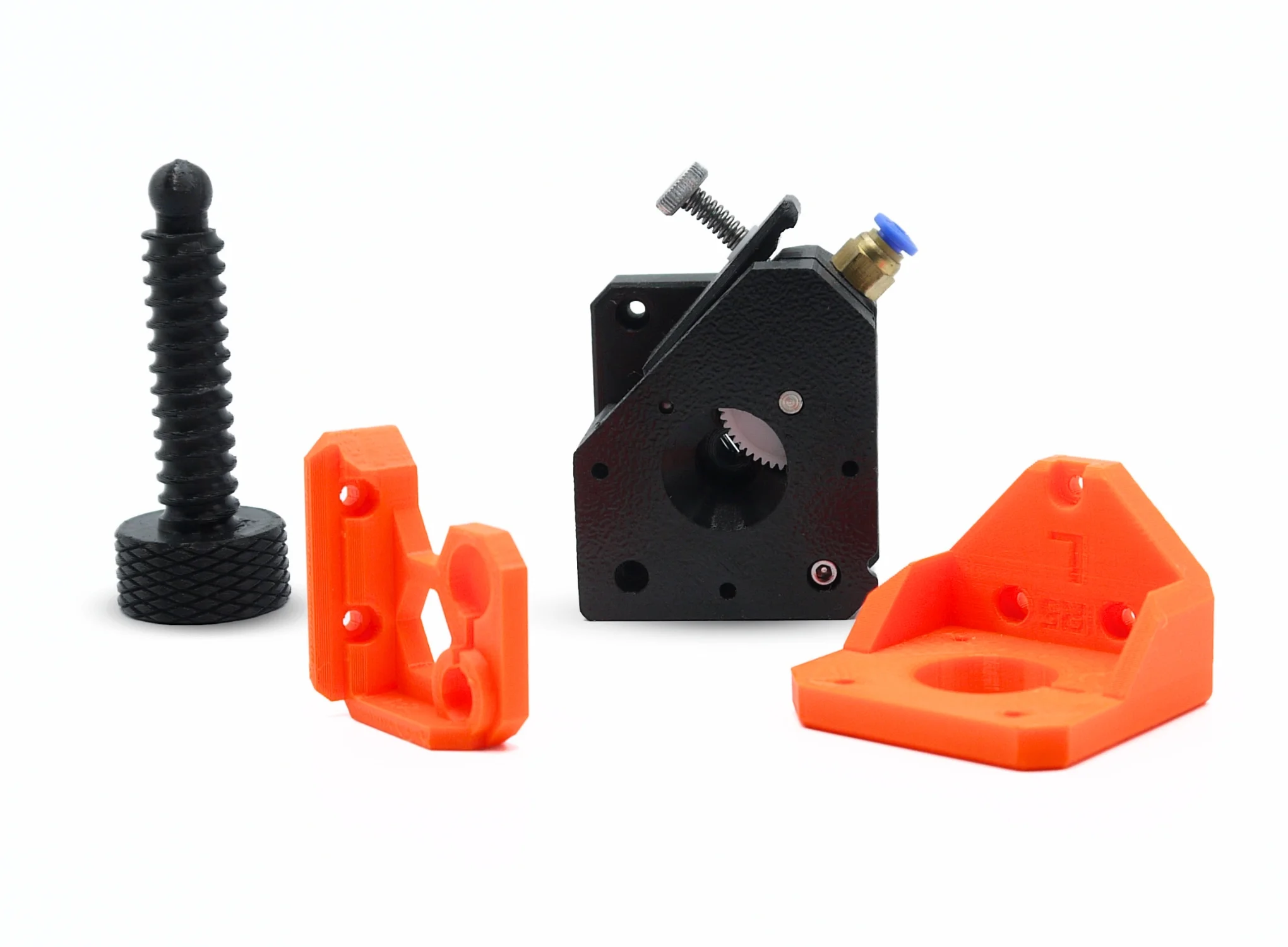

3D printing

What is 3D printing?

3D printing is a process that creates three dimensional objects from a digital design, building the part layer by layer. It is ideal for functional prototypes, complex geometries and on demand production, without the need for molds or tooling.

Benefits of 3D printing

- Wide range of technologies available such as FDM, SLA, SLS, MJF and DMLS.

- Ideal for validating designs or producing short runs without molds.

- Professional finishes ready for functional use.

CNC machining

What is CNC machining?

CNC machining, or Computer Numerical Control machining, is used to manufacture metal or plastic parts with digitally controlled cutting tools. We run CNC processes with micrometric precision, ideal for technical components, molds, tools and final parts.

Benefits of CNC machining

- Direct production from drawing or 3D model.

- Custom finishes such as anodizing, sandblasting, painting and more.

- Milling and turning in a wide range of materials.

Injection molding

What is injection molding?

Injection molding is a manufacturing process used to produce plastic parts in high volumes. The material is melted and then injected at high pressure into a mold.

Benefits of injection molding

- Molds custom designed from your drawings.

- Compatible with the main technical thermoplastics.

- Consistent parts in large volumes.

Sheet metal bending

What is sheet metal bending?

Sheet metal bending is a plastic deformation process used to fold a metal sheet to create a three dimensional shape, applying controlled force without removing material.

Benefits of sheet metal bending

- Custom bending radii according to thickness.

- Ideal for structures, housings and metal brackets.

- Increases the structural strength of the sheet.

Laser cutting

What is laser cutting?

Laser cutting is a digital manufacturing process that uses a concentrated and high power beam of light to cut, engrave or mark materials with high precision.

Benefits of laser cutting

- Enables very precise cuts with fine details.

- Full repeatability for short and medium series.

- Ideal for flat parts, structures and prototypes.

Waterjet cutting

What is waterjet cutting?

Waterjet cutting is an industrial process that uses a high pressure jet of water, often mixed with an abrasive, to cut a wide variety of materials with precision and without generating heat.

Benefits of waterjet cutting

- Effective solution for thick materials or parts that are sensitive to heat.

- Clean cut without altering mechanical properties.

- Allows thicknesses up to 100 mm with a uniform finish.

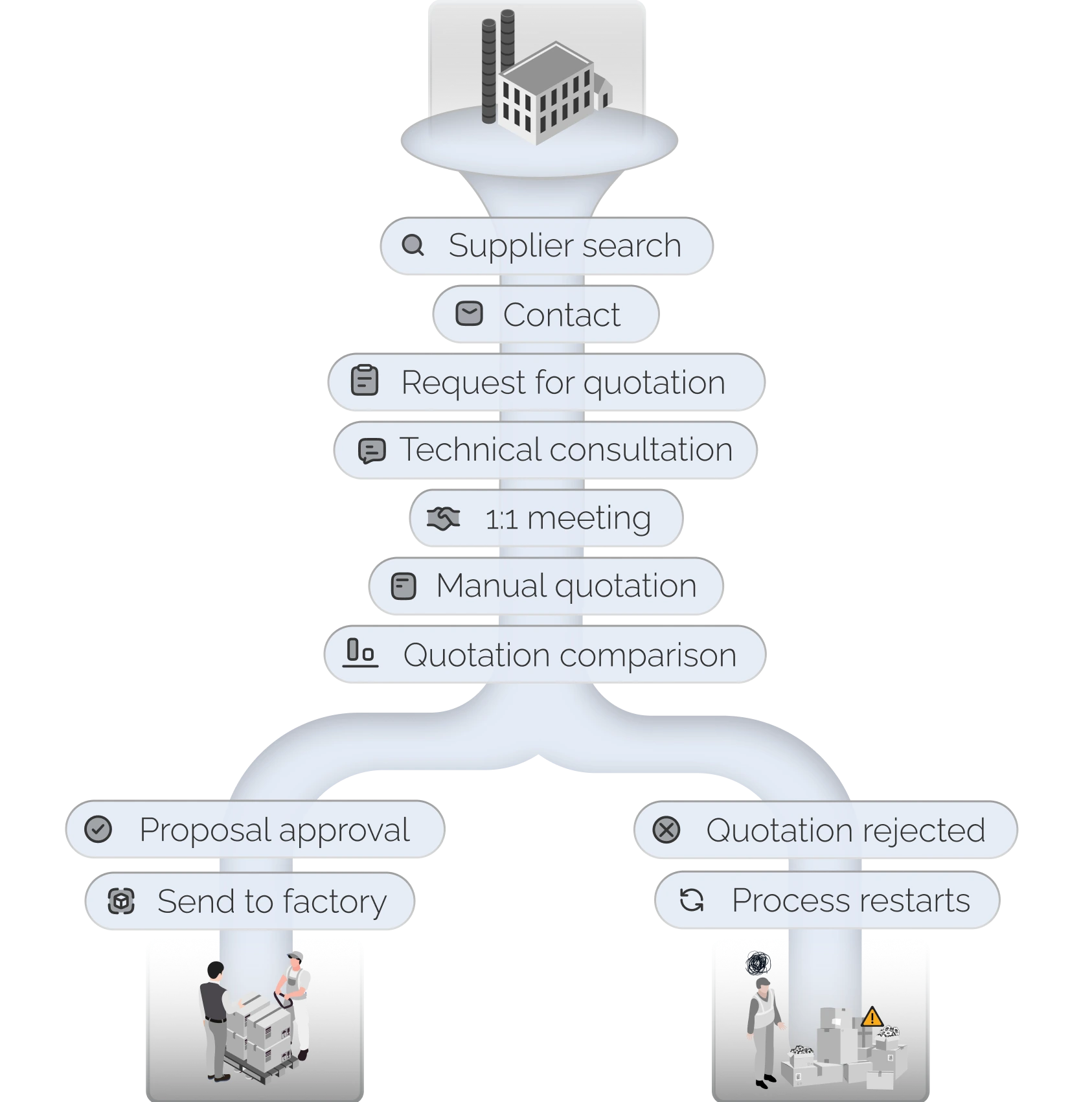

WHY MANFACTER

Streamline your manufacturing process

WITH MANFACTER

Takes weeks to

get your parts

Takes weeks to get your parts

WITHOUT MANFACTER

Takes weeks to

get your parts

Get your parts 90% faster

in just a few days

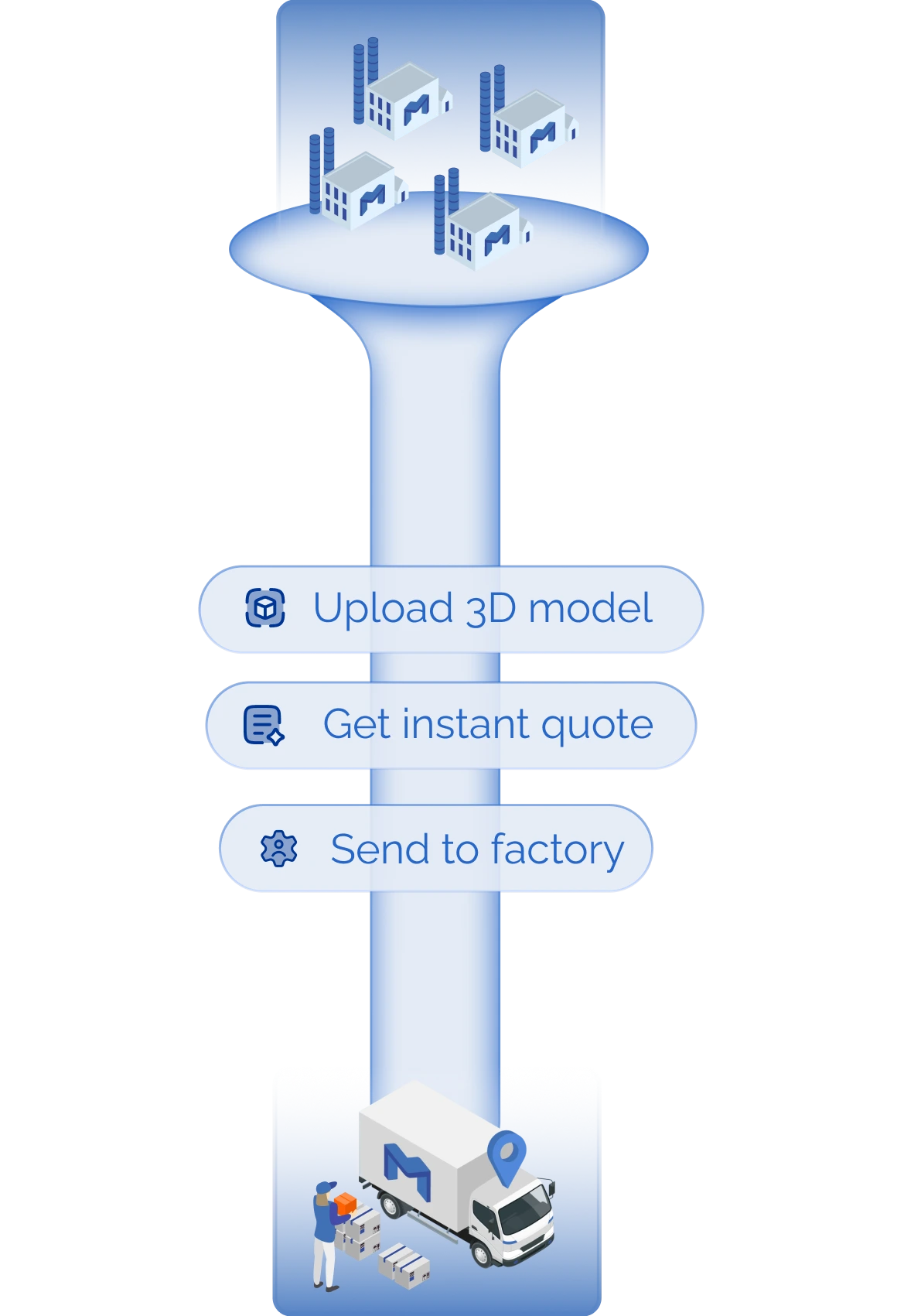

HOW IT WORKS

Manufacture with us in three simple steps

Upload your 3D model

We support STL files.

All uploaded data is fully protected.

Set your specifications

Choose from a wide range of materials, finishes, and post-processing options.

Receive your parts

We manufacture your order under the highest quality standards.

+50k

Parts manufactured

200

Orders completed

+10

Available materials

REVIEWS

What our customers say about us

Very satisfied with the quality of the parts

The online platform for ordering 3D printed parts is very easy to use, yet flexible and complete in its options. Every time I’ve used it, it has run smoothly without any glitches. Payments are made through a fast and secure gateway, and you instantly receive order confirmation emails.

What really makes this company stand out is the finish quality, it’s outstanding. They’re truly committed to delivering the best possible part these technologies can achieve, nothing like the results from hobby-grade printers.

I 100% recommend this company’s services. …Ver más

Teo Tormo Gea

A 10

The platform works perfectly, much faster and more intuitive than with my previous supplier. Both customer service and product quality have always been impeccable.

I’ll definitely order again. Thank you!

Marcos Gran

Excellent platform and service

Outstanding service, the platform works flawlessly, very intuitive and efficient. The parts arrived on time and with top-tier quality.

Highly recommended.

Rodrigo Ruano