Types of inserts for plastics

Standard inserts are those that comply with the dimensions, materials, and designs established by the industry. They are commonly used in plastic parts produced by 3D printing, injection molding, or CNC machining.

Among the most common inserts on the market are:

When selecting the most suitable type of insert, it is essential to consider two key factors: pull-out resistance and torque resistance.

-

- Pull-out resistance: refers to the insert’s ability to remain in its housing without coming loose when the screw is tightened. This resistance increases with the length of the insert, since a larger contact surface with the material improves fixation.

- Torque resistance: refers to the insert’s ability to prevent rotating within its housing when torque is applied to the screw. A greater insert diameter provides higher torque resistance, as the increased contact surface with the material enhances fixation.

In addition to these factors, it is important to analyze the insert’s size and diameter, for which consulting the manufacturer’s datasheet is recommended. It is also crucial to evaluate the materials—both of the insert and the base material in which it will be installed. Inserts are designed for a wide range of materials, including metals, plastics, and wood. In terms of manufacturing, brass is the most common material, although there are also options in stainless steel (with high corrosion resistance) and aluminum (lighter weight).

Press-Fit Inserts

Press-Fit Inserts are designed to be installed into post-molded holes without the need for heat, making them ideal for softer plastics. These inserts feature knurls that provide high resistance to both torque and pull-out, ensuring secure anchoring to the plastic.

- Standard Press-Fit Inserts: Feature helical knurls that bite into the plastic when pressed in, guiding the insert to achieve a firm and stable fit.

- Expanding Screw Inserts: Designed with diamond knurls and expanded by inserting a screw, providing an even more secure fit within the surrounding plastic.

These inserts allow for quick installation without the need for specialized tools and deliver reliable performance for secure fastening.

Press-Fit Inserts Applications

- Consumer Electronics and Device Housings: In products such as mobile phones, laptops, cameras, and appliance casings, Press-Fit Inserts enable durable fastening without damaging the plastic. Most of these devices require assemblies that allow disassembly for maintenance or repair without compromising thread integrity.

- Medical Equipment and Biomedical Devices: Press-Fit Inserts are used in housings for medical devices, laboratory equipment, and prosthetics where reliable, high-precision fastening is required. Many of these products are made from engineering plastics that cannot withstand high temperatures, making Press-Fit Inserts an ideal alternative to heat-set inserts.

- Automotive and Aerospace Components: In the automotive and aerospace industries, Press-Fit Inserts are applied in parts such as interior panels, dashboards, sensor housings, and reinforced plastic assemblies. These components must withstand constant vibrations and temperature fluctuations without the fastening loosening.

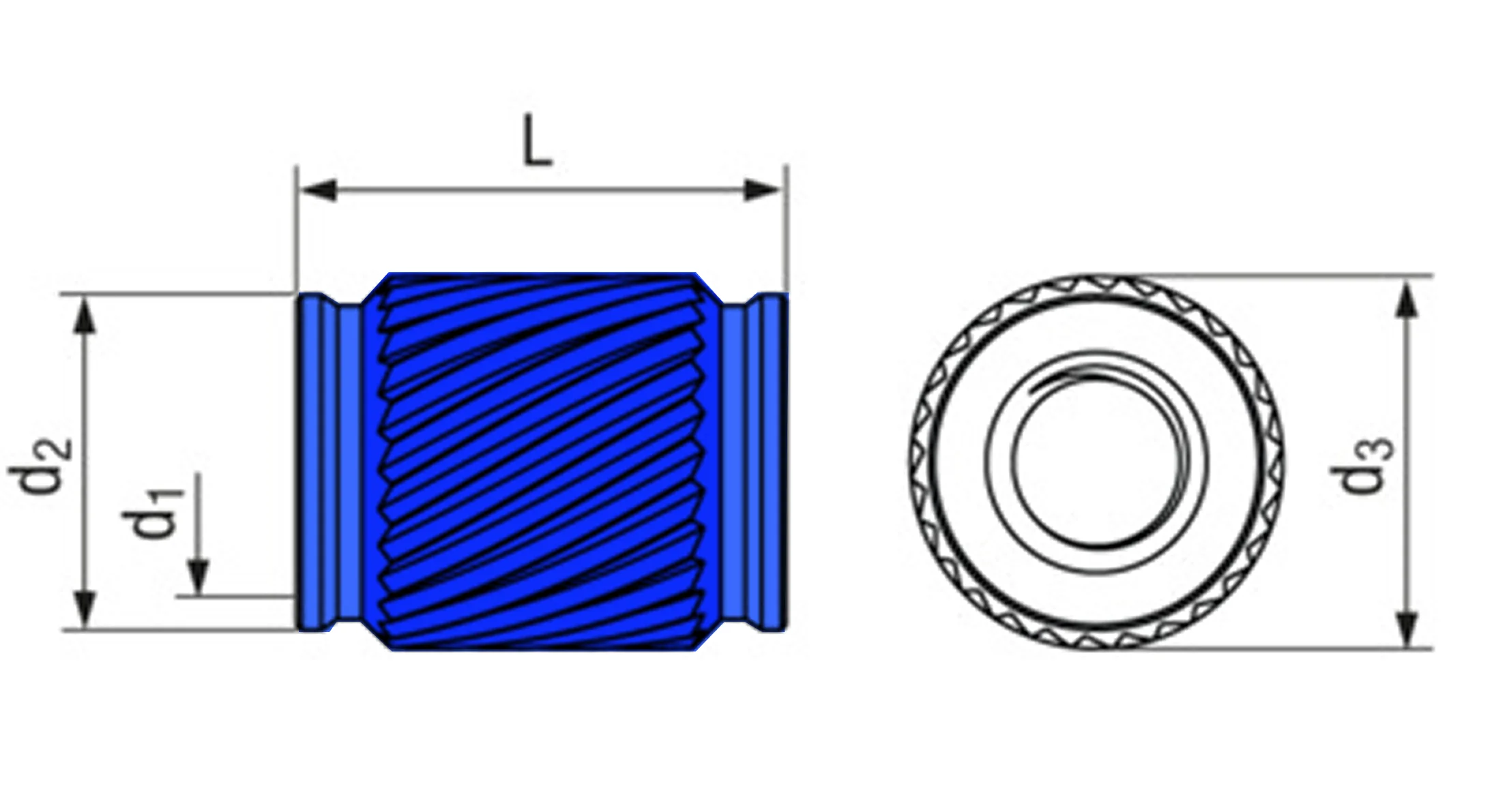

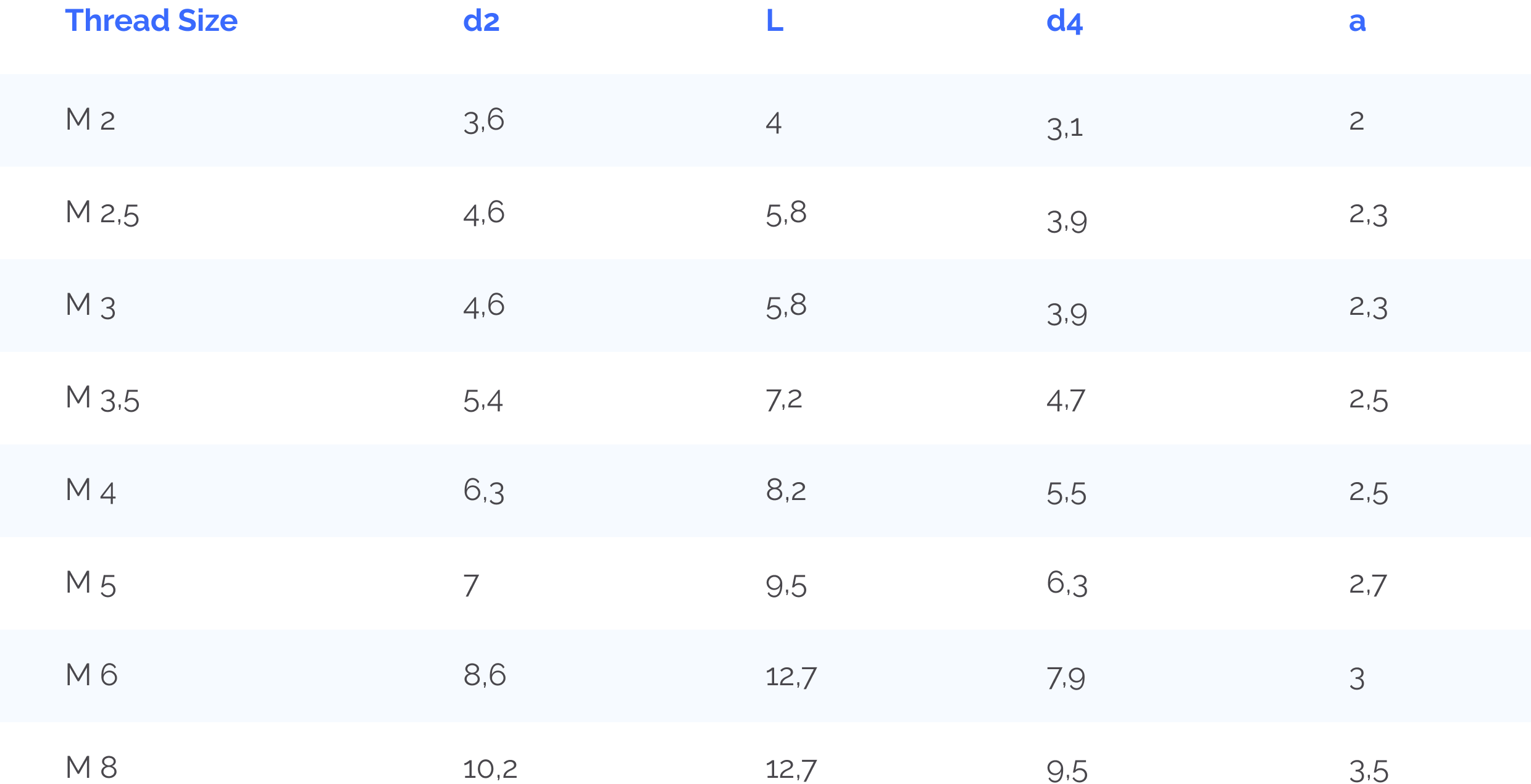

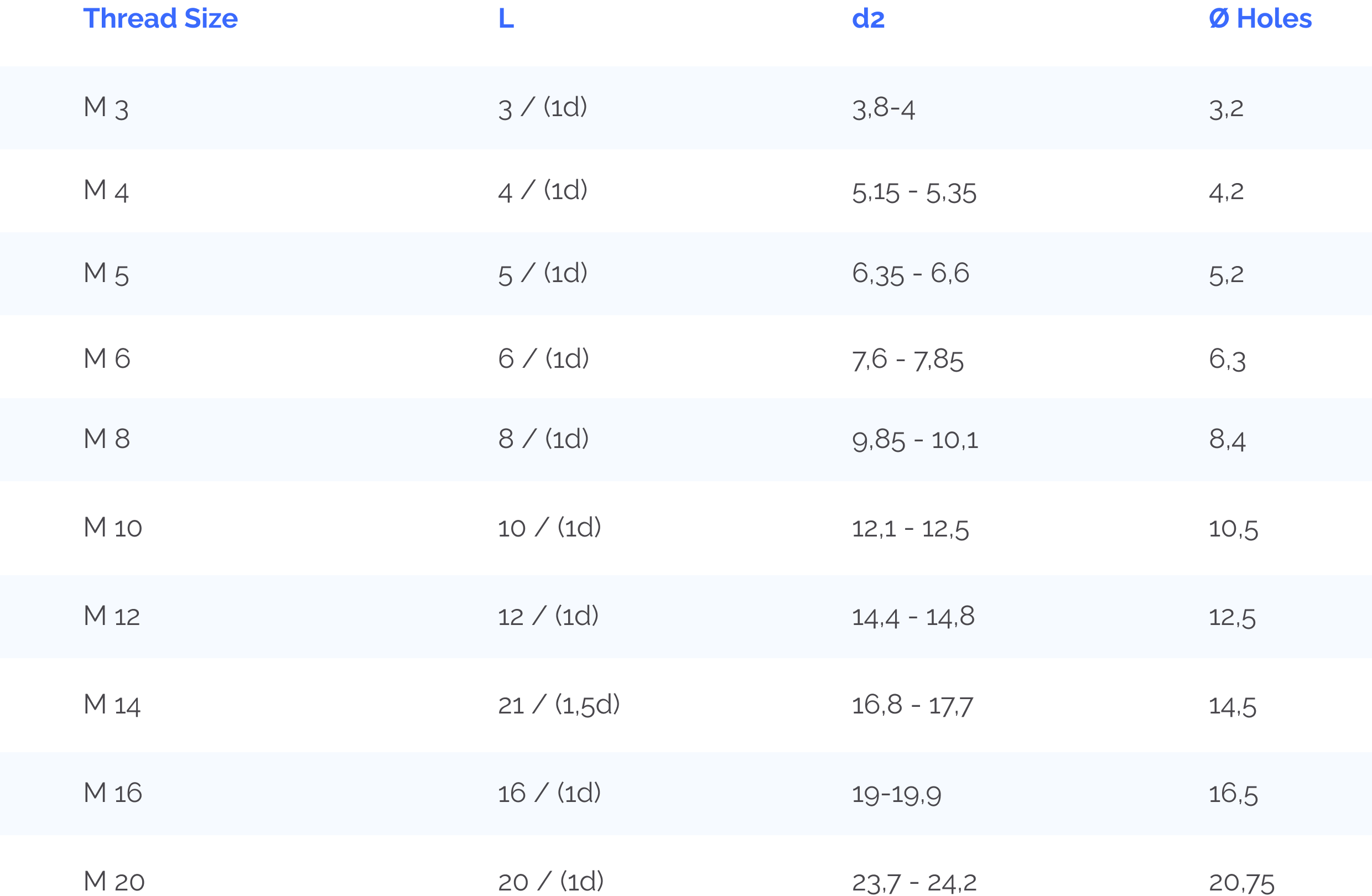

Standard Sizes of Press-Fit Inserts

The following table shows the most common insert sizes used in industry. For exact specifications, please refer to your supplier’s datasheets.

** The data has been taken from the insert supplier Bossard

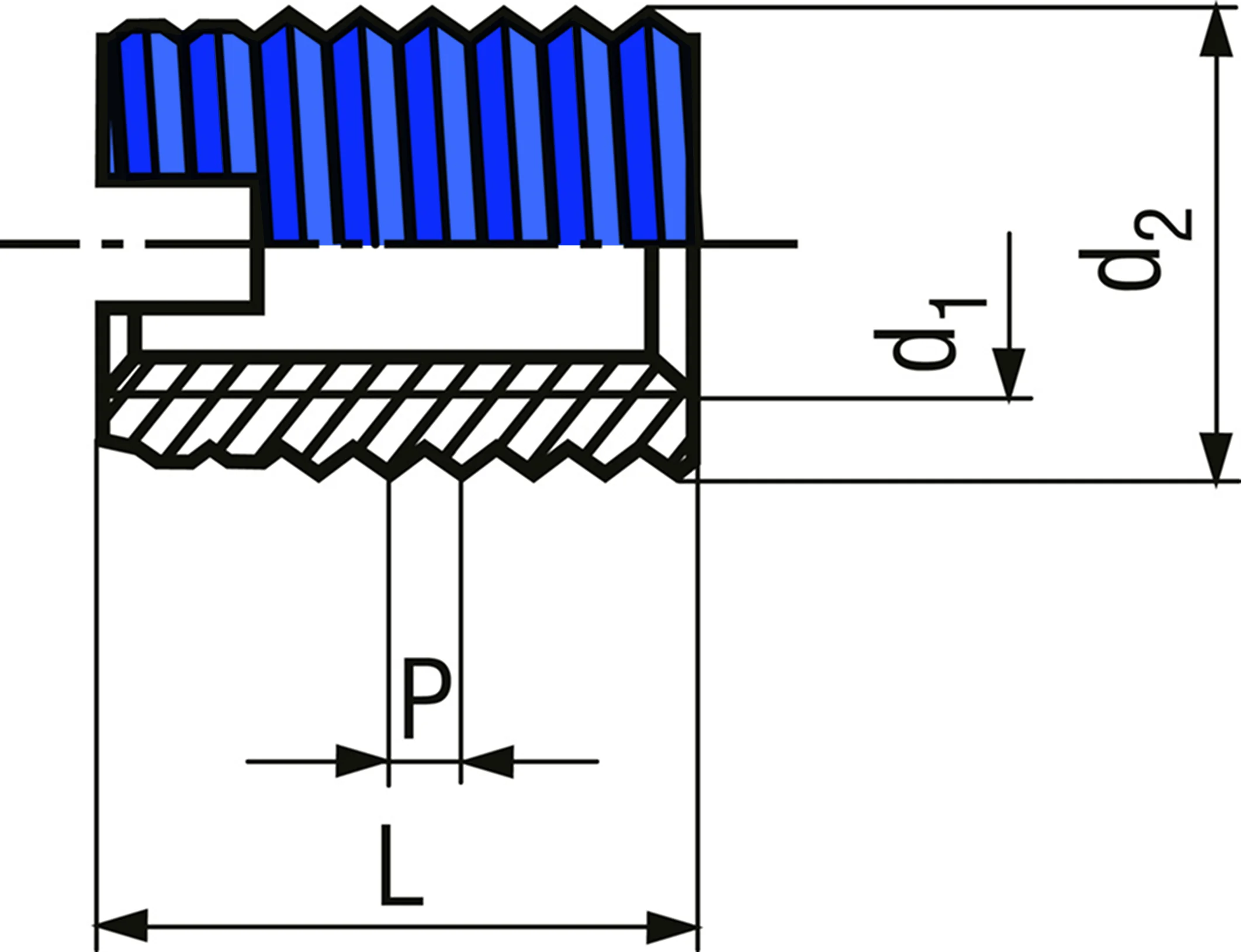

Heat-Set Inserts

Heat-Set Inserts are installed by heating them and then pressing them into pre-molded holes in plastic parts. Once cooled, the insert bonds firmly to the surrounding plastic, creating a solid anchor point for fasteners.

These inserts are ideal for thermoplastics used in 3D printing, as the plastic melts and flows around the insert during installation, forming a strong connection. This process reinforces the area around the insert, ensuring a secure bond between the metal insert and the plastic material.

There are two main installation methods:

- Heat-Setting: A thermal press is used to heat the insert and press it into the plastic, melting a small amount of material around it. The molten plastic flows into the knurling of the insert and solidifies once the press is removed, forming a strong connection.

- Ultrasonic Insertion: Uses high-frequency vibrations to generate heat and melt the plastic. However, this method is less common due to the difficulty of automation and the precise control it requires.

Among the most common types of inserts used for heat-setting or ultrasonic insertion, straight and tapered inserts stand out. Tapered inserts are particularly useful, as their design allows for self-alignment, enabling faster and more efficient installation.

Heat-Set Inserts Applications

- Tools: Many portable tools, such as electric screwdrivers, drills, heat guns, and power saws, are made with high-strength polymer housings. To ensure that screws do not loosen under frequent use and vibration, Heat-Set Inserts are used at assembly points.

- Consumer Products: Heat-Set Inserts are found in quality toys such as building blocks (e.g., LEGO®), recreational drones, and mechanical toys, where it is essential for screwed joints to withstand constant use without degrading.

- Modular Furniture and Design Assemblies: Heat-Set Inserts are essential in modern plastic and composite furniture, such as ergonomic chairs, modular desks, and assemble-yourself shelving, where screws must maintain a firm hold without damaging the base material.

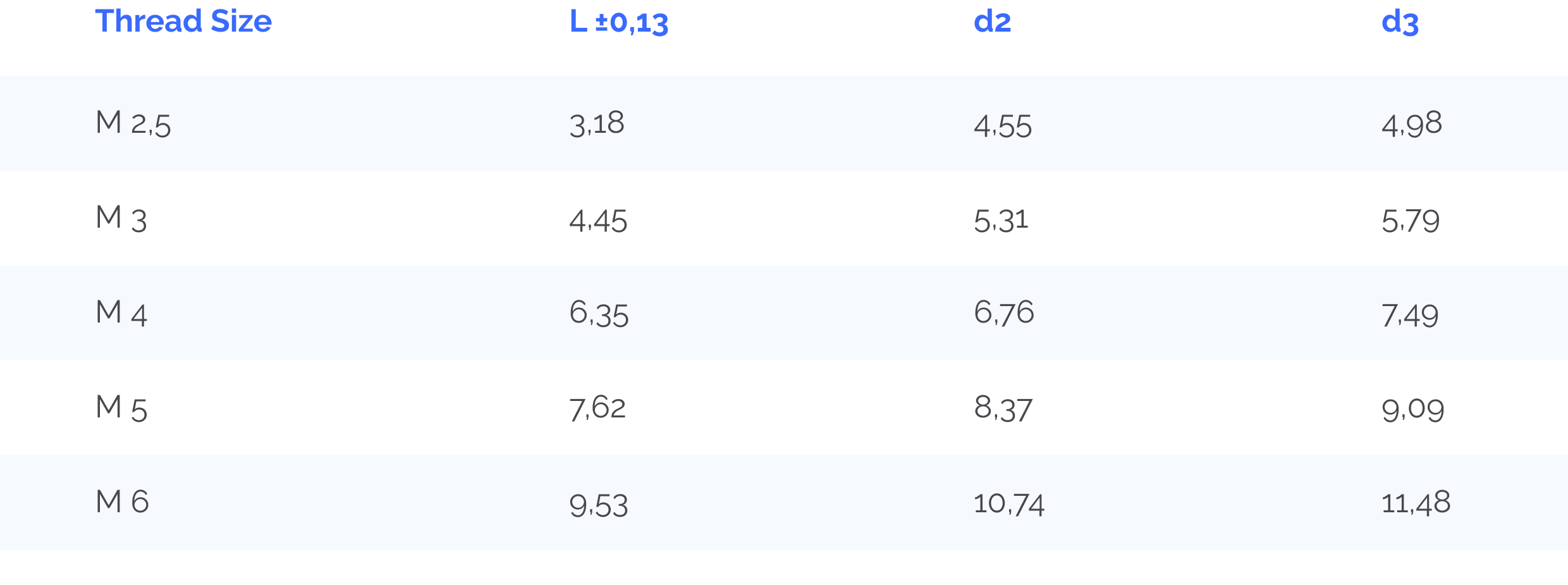

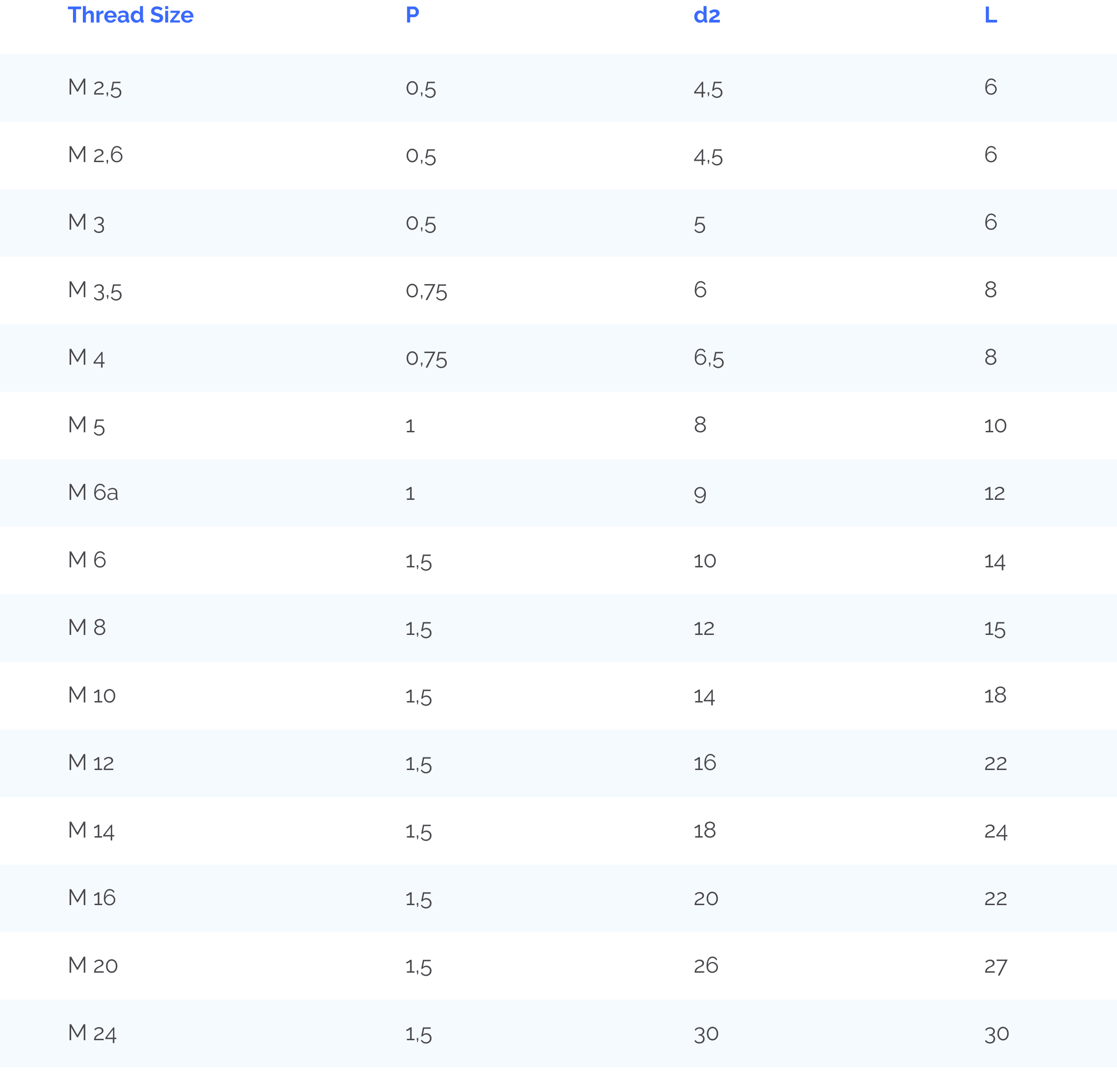

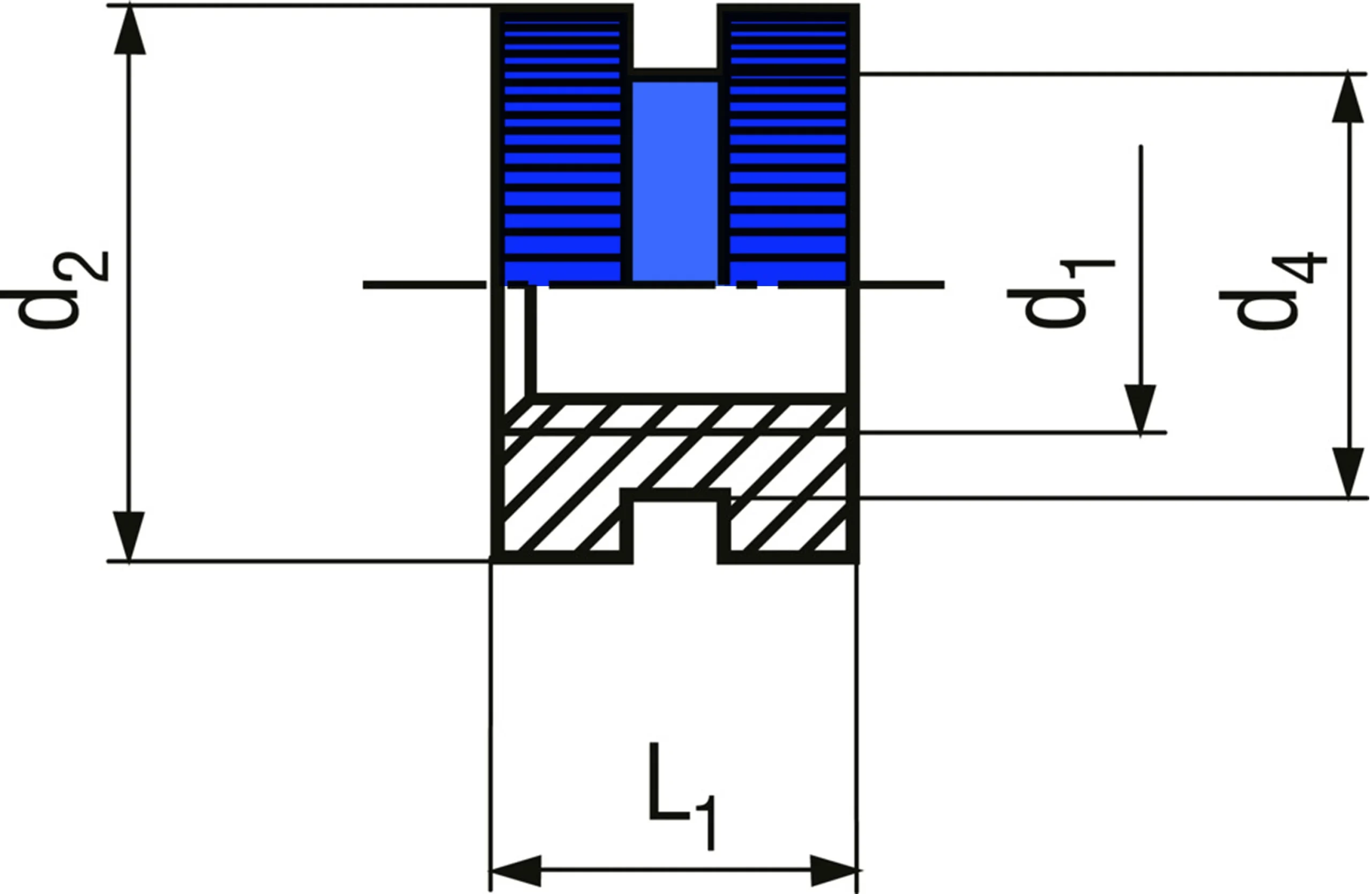

Standard Sizes of Heat-Set Inserts

The following table shows the most common insert sizes used in industry. For exact specifications, please refer to your supplier’s datasheets..

** The data has been taken from the insert supplier Bossard

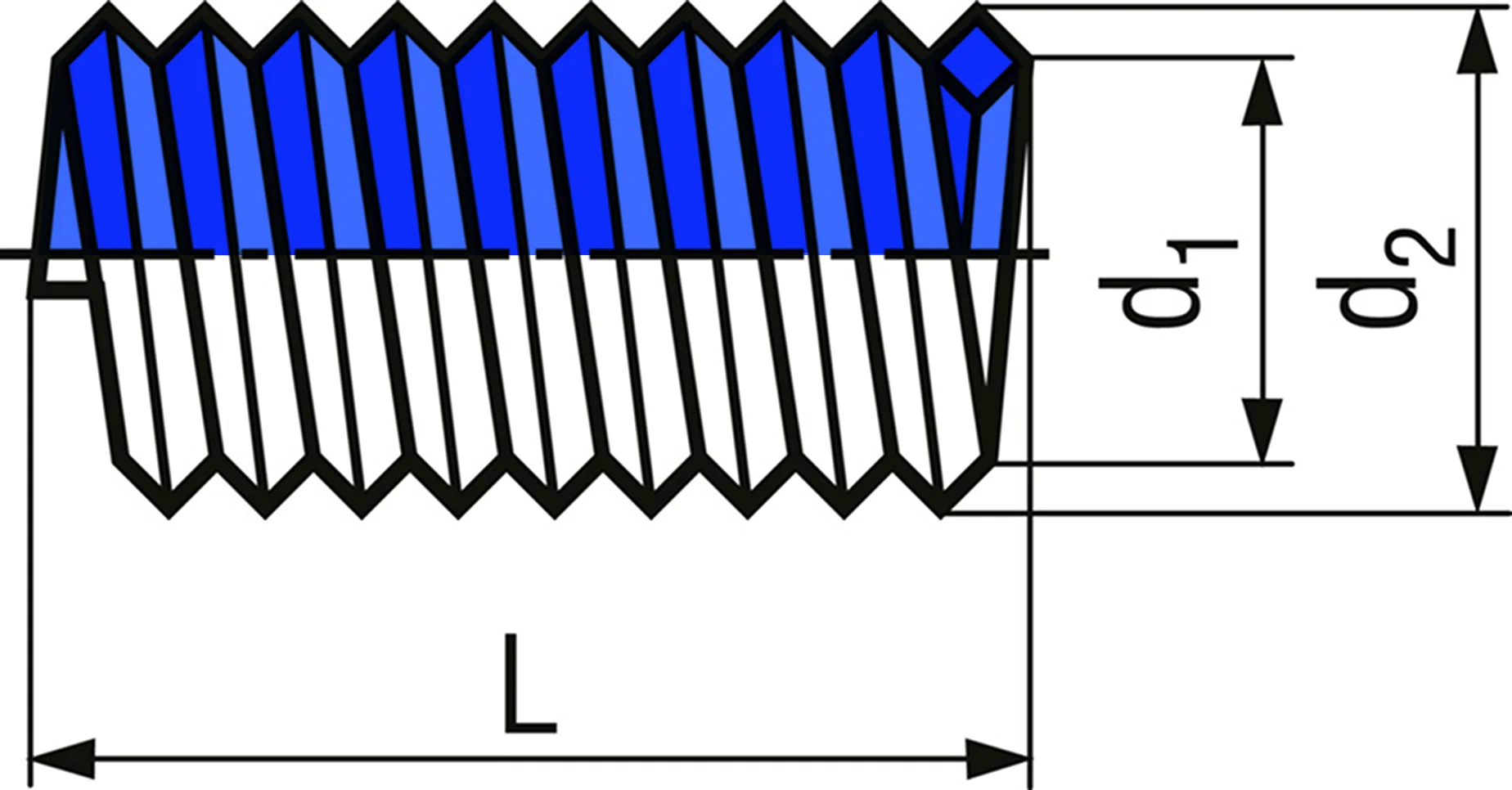

Tapped Inserts

Self-Tapping Inserts are installed after molding and are notable for providing excellent pull-out resistance. Their external thread design minimizes stress on the plastic, while the coarse pitch maximizes shear surface area, reducing the risk of pull-out. These inserts are ideal for softer thermoplastics or thermosets, helping to prevent cracking.

Installation torque is not a significant concern, as tightening the screw generates enough friction between the insert and the plastic to ensure a secure fit. The larger diameter of the external thread increases the friction surface, while torque performance depends on the contact area between the threads and the plastic.

Tapping Insert Applications

- Sports Equipment: Threaded Inserts are used in the manufacturing of bicycles, skateboards, helmets, climbing gear, and other sporting goods, especially those made with reinforced plastics or aluminum components. These inserts ensure that screwed joints remain durable and resistant to impacts and vibrations.

- Lighting Devices and LED Fixtures: Modern lighting systems, including industrial LED lights, automotive headlights, and outdoor lamps, require robust housings capable of withstanding high temperatures and harsh environmental conditions. Threaded Inserts enable strong assemblies in high-performance plastics such as polycarbonate or glass-fiber-reinforced polyamide.

- Home Appliances and Kitchen Tools: Modern appliances such as blenders, mixers, coffee machines, and food processors are often made from high-strength plastics. Threaded Inserts ensure strong screw joints, especially in parts subject to repetitive stress, such as lids, supports, and detachable bases.

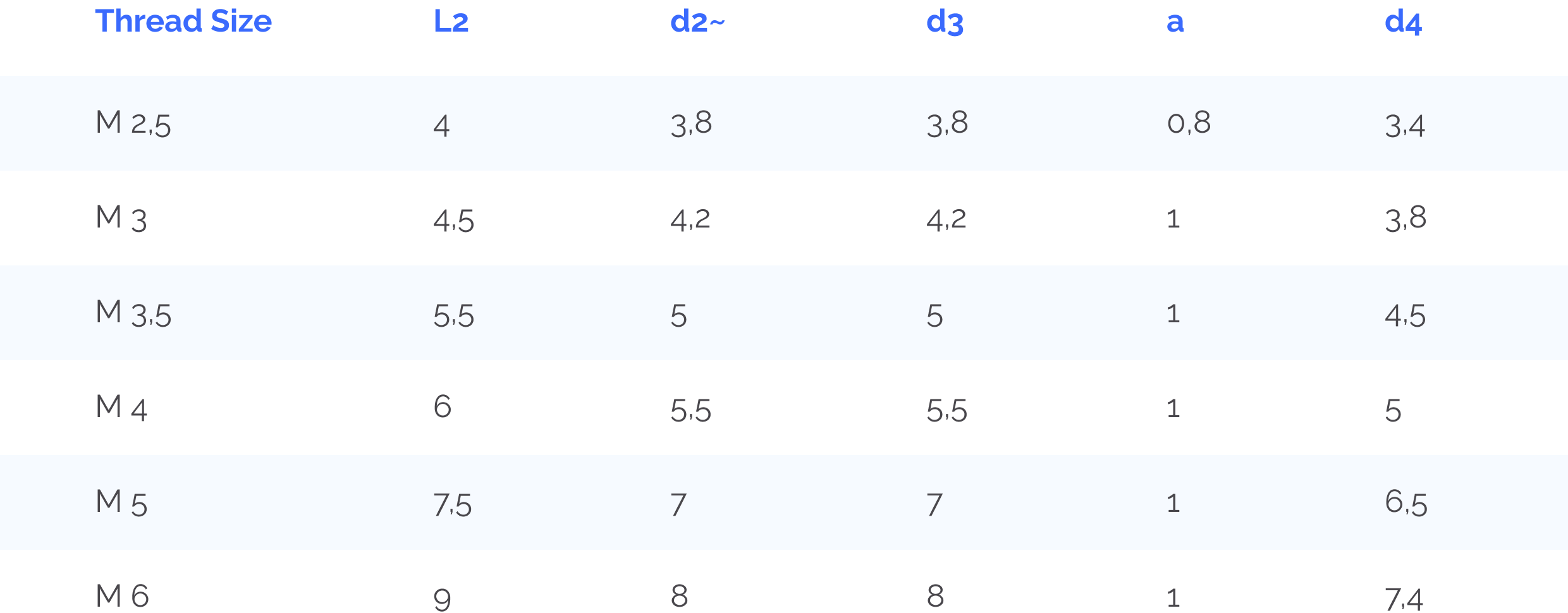

Standard Sizes of Tapping Inserts

The following table shows the most common insert sizes used in industry. For exact specifications, please refer to your supplier’s datasheets.

** The data has been taken from the insert supplier Bossard

Helical / Helicoil® Inserts

Helical Inserts, also known as spiral inserts or threaded inserts, are coil-shaped components made from materials such as stainless steel or brass. These inserts are ideal for reinforcing or repairing damaged threads in plastic components, providing a durable solution that restores the integrity of threaded connections in a wide range of applications.

Helical Insert Applications

- Engine and Cylinder Block Repair in the Automotive Industry: In internal combustion engines and other mechanical components of cars and motorcycles, many threads are located in aluminum parts, a lightweight material prone to wear over time. When a thread in a cylinder block, cylinder head, or transmission housing is damaged, Helical Inserts make it possible to repair it without replacing the entire part.

- Aerospace Industry and Aviation Applications: Aircraft require components that are both lightweight and strong, which is why many structural parts are made from aluminum and titanium alloys. However, these materials can suffer thread wear due to constant vibration and mechanical loads. Helical Inserts create more durable threads in parts subjected to high stresses and frequent maintenance cycles.

- Power and Energy Generation Equipment: Generators, turbines, and other power production equipment are often exposed to high temperatures, vibrations, and dynamic loads, which can lead to thread wear in housings and structures. Helical Inserts reinforce or repair these threads without the need for costly part replacements.

Standard Sizes of Helical Inserts

The following table shows the most common insert sizes used in industry. For exact specifications, please refer to your supplier’s datasheets.

** The data has been taken from the insert supplier Bossard

Molded-In Inserts

Molded-In Inserts are used in the injection molding process, where pins are machined or placed into the mold core. During molding, the inserts are fully encapsulated by the resin, resulting in a high-quality bond and eliminating the need for additional post-molding insertion steps.

However, this process requires a more complex core design and precise tolerances between the pins and inserts. In addition, placing the inserts during each cycle can be a time-consuming process.

Although initial costs are higher compared to post-molding installation methods, Molded-In Inserts deliver superior performance. Their design significantly impacts pull-out and torque resistance, particularly in terms of length and diameter. Helical knurled inserts are often preferred to maximize torque resistance at a given diameter. Proper encapsulation of the plastic into the insert’s undercuts is essential to achieve the necessary pull-out strength during use.

Molded-In Insert Applications

-

Laptop and smartphone housings: Provide durable screw threads in thin plastic casings.

-

Automotive dashboards and panels: Ensure vibration-resistant fastening in interior plastic parts.

-

Household appliances: Used in washing machines, vacuum cleaners, and blenders for secure joints in high-stress areas.

-

Medical equipment casings: Allow repeated assembly/disassembly without damaging the plastic.

-

Power tools: Strengthen fastening points in polymer housings of drills, saws, and screwdrivers.

-

Furniture assembly: Offer strong threaded connections in modular plastic and composite furniture.

Standard Sizes of Molded-In Inserts

The following table shows the most common insert sizes used in industry. For exact specifications, please refer to your supplier’s datasheets.

** The data has been taken from the insert supplier Bossard

Add Inserts to Your Parts with Manfacter

- Select the part where you want to add the insert.

- Locate the insert field in the central configuration panel.

- Añade el plano 2D de la pieza en el que se especifique la ubicación de cada inserto.